Graco Sprayers

Nukote Industries (Shanghai) is an authorised Graco distributor in China. You can find the equipment for spraying a wide range of protective coatings. We provide high performance plural component sprayers such as airless pumps, Husky pumps, process equipment, finishing equipment, and industrial lubrication equipment. We are committed to provide a full range of service including equipment handling, site support, repair & maintenance, spare parts, and demonstration.

Nukote Industries (Shanghai) is an authorised Graco distributor in China. You can find the equipment for spraying a wide range of protective coatings. We provide high performance plural component sprayers such as airless pumps, Husky pumps, process equipment, finishing equipment, and industrial lubrication equipment. We are committed to provide a full range of service including equipment handling, site support, repair & maintenance, spare parts, and demonstration.

Find the right plural component equipment for your project. We guarantee your satisfaction.

Graco equipment is designed for durability, high performance and precision. Find equipment for spraying:

- Spray foam insulation applications

- Roofing projects

- Polyurea and polyurethane coatings, including waterproof coatings and linings

- High performance coatings

- Protective coatings

- Epoxy intumescent fireproofing coatings

- 2-component materials

Graco Selection:

Reactor E-10hp

High-Pressure Coating Equipment for Polyurea

Entry-level system for pure and hybrid polyurea coatings

Grow your business with polyurea applications

The Reactor E-10hp is an ideal entry-level system and is great for coating projects such as balconies, pools, waterproofing and bedliner applications. It’s a smart, affordable investment that will help your business grow.

Even though it’s an entry-level system, it still packs plenty of power. The Reactor E-10hp adds high pressure to give you the power and performance you need to spray polyurea coatings. This compact unit is lightweight and portable – and even runs on residential power so you don’t need to invest in a generator.

Feature:

- Ideal for small to medium projects such as terraces, pools, balconies,

tanks, truck bedliners, secondary containment and waterproofing - Heats material fast

- Portable and easy to use

- Uses standard residential electrical outlets – no generator needed

- Affordable investment – compared to a standard Reactor which requires a generator and spray rig

Boost heat for fast, 20-minute start-up times

With the system’s innovative boost heat and insulated tanks, material heats up fast so you’re up and running sooner. In fact, you’re ready to spray in a fraction of the time, compared to over an hour start-up time on a standard Reactor E-10.

Reactor E-XP2i

Integrated Proportioning System

Turnkey system for polyurea waterproof coating and lining – applies up to 2 gal (7.6 liters) per minute

The integrated series of Reactors combines an electric proportioner and diesel generator into one innovative, cost-saving system. It’s ideal for polyurea coating applications, including waterproofing and waterproof linings.

The integrated series of Reactors combines an electric proportioner and diesel generator into one innovative, cost-saving system. It’s ideal for polyurea coating applications, including waterproofing and waterproof linings.

Integrated design re-purposes wasted heat and saves energy

- System pulls the heat from the diesel engine to heat the A and B materials, reducing electrical demand on the generator

- Since there are no heaters (or only small heaters) on the proportioner, this reduces the electrical demands of the generator, allowing a smaller generator to be used

- The system’s smaller 20 kw generator uses less fuel than a standard 30 or 40 kw generator

- You benefit from an annual fuel savings on average of $7,000 (actual savings may vary)

Features:

- Smaller generator saves diesel fuel costs

- Improves productivity with advanced features and easy to use controls

- Eliminates guesswork – totally engineered and tested by Graco

- Eliminates costly power issues associated with shore power and low cost generators

- Fast material heating gets you up and running quicker

- Improves spray performance with consistent pressure at the gun

- Complete turnkey models are available with an integrated air compressor

Advanced controls

- Tracks project information

- Lets you download data onto a USB drive for further analysis

- Stores up to 24 chemical recipes

- On-screen troubleshooting advice

- Flexible system settings

Fast material heating

- With just one pass through the heat exchanger, materials can be heated to a Delta T of 100 degree Farenheit (55 C)

- This improved heating capacity means you can start spraying sooner

Reactor 2 E-XP2i

Integrated Proportioning System

Turnkey system for polyurea waterproof coating and lining – applies up to 2 gal (7.6 liters) per minute

The integrated series of Reactor 2 systems combines an electric proportioner and diesel generator into one package – an innovative, cost-saving design. In addition, the system offers the many advantages of the revolutionary Reactor 2 design.

Integrated design repurposes wasted heat and saves energy

- System pulls the heat from the diesel engine to heat the A and B materials, reducing electrical demand on the generator

- The system’s smaller 20 kw generator uses less fuel than a standard 30 or 40 kw generator

- You benefit from an annual fuel savings on average of $7,000 (actual savings may vary)

Feature:

- Energy-saving integrated design

- Graco InSite Remote Reporting Technology

- Inlet pressure and temperature sensors

- Advanced control module

- Stores up to 24 chemical recipes

- Easy-to-see drum level indicators

- More compact design

- New multi-zone heater control module

- Brushless DC motor

- On-screen QR codes for faster troubleshooting information

- Extreme-Wrap scuff guard

- Hydrovane tankless air compressor (optional)

- Refrigerated air dryer (optional)

Reactor 2 advanced features can revolutionize the way you run your business

Each feature in the Reactor 2 was strategically designed to help your business, with innovations that help your operation run smoothly. Software and hardware enhancements for better spray performance. And new technologies that add to your bottom line.

- Better control – with Graco InSite remote reporting, you can manage your spray foam or polyurea business wherever you are

- Better documentation – collect job log data automatically and confirm you sprayed to specifications

- Compact footprint – more room in your spray rig

- Advanced controls with more visible information and tracking capabilitiy

- Ergonomic design – easier maintenance and service

- Better spraying performance compared to traditional electric Reactor systems

- Advanced circuit boards – minimize pressure fluctuations

- Better management of fleet, crew, cost containment and forecasting

- Troubleshooting made quick and easy with QR codes

- 3-year warranty on major electronic components

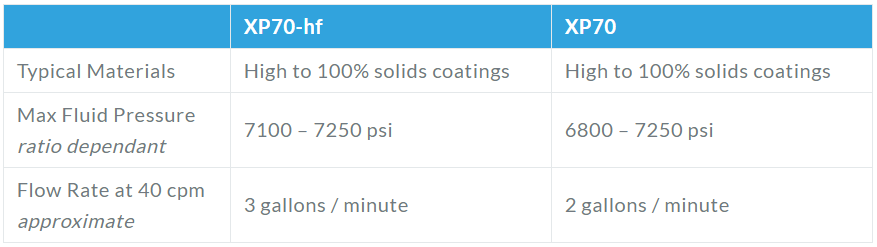

XP70 and XP70-hf Plural-Component Sprayers

Two-component spraying made easy and affordable

High-pressure performance for two-part high-solids coatings

A smart alternative to hand mixing

The Graco XP70 Plural-Component Sprayer is designed to pump, mix and atomize high to 100% solid coatings with superior results. In addition, the XP70’s design allows you to gravity feed, which may eliminate the need for feed pumps, saving you money. When you upgrade from hand mixing, you’ll find that the XP70 provides excellent return on investment, by reducing material waste and by using less clean-up solvent.

The XP-hf system combines the popular XP70 Sprayers with the powerful XL 10000 air motor. Combining these two technologies, you get more flow – getting jobs done faster and with less wear and tear.

Engineered for more flow capacity, the Graco XP70-hf is great for applications where you want to spray with multiple guns or larger tip sizes.

Flexible options for mix ratio, pressure and flow rate – choose the right system for the application. If you occasionally change materials, the Graco XP Sprayers are the right choice. That’s because you can change the ratio by simply changing out one or two pump lowers. Available in 1:1, 1.5:1, 2:1, 2.5:1, 3:1 and 4:1 mix ratios.